Lecture

The matrix printer (MP) is a complex microprocessor electronic-mechanical device, assembled on a modern electronic base using optoelectronics, stepper motors (SD), an electromechanical drive.

The matrix printer implements a shock method of image registration.

Figure 73 - Matrix Printer Block Diagram

The main components of the printer and their relationship are shown in Figure 72.

Diagnostics of malfunctions and repair of the matrix printer

To initialize the printer, you must either turn on the power switch, or send an L-level RESET signal via the interface cable.

When the printer is initialized, the following actions occur:

Sound alarm

Buzzer buzzers inform the operator about the following events:

The printer goes into an alarm state when:

Troubleshooting should be carried out from simpler elements to more complex and costly according to a predetermined plan. The method of successive exclusion of components suspected of failure is preferred, if there are obviously corrected components for replacement. Failures in electronic components are usually quite simple. The causes of faults are most often:

violation of the timing diagram of the node or component.

Printer lubrication

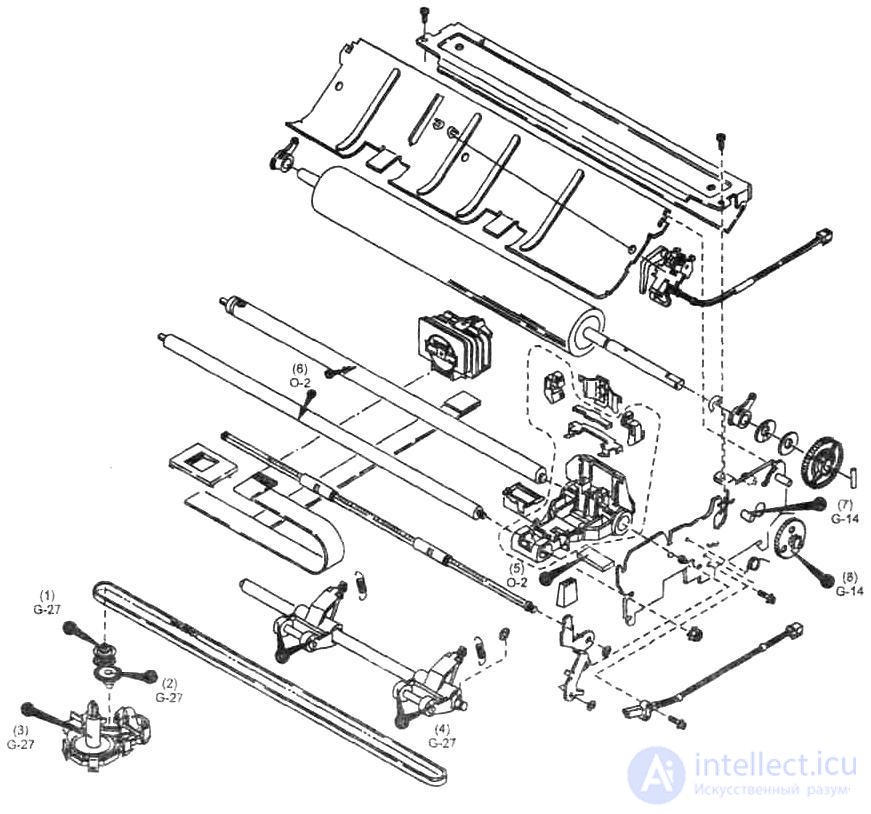

EPSON recommends that parts at the points shown in the figure be lubricated according to schedule using lubricants that have been tested over a wide range and that meet the requirements of a printing device.

It is necessary to regularly lubricate at intervals A and B in the table. You must ensure that the parts called are clean before applying the lubricant, and avoid over-applying, which can damage the connected parts.

|

No |

Lubrication points |

Lubricant |

Interval |

|

one* |

The contact part of the shaft of the pulley belt drive and E- |

G-27 |

AT |

|

|

rings |

|

|

|

2 * |

The contact part of the planetary gear painting |

G-27 |

AT |

|

|

tape and shaft |

|

|

|

3 * |

The contact part of the drive ribbon drive and |

G-27 |

AT |

|

|

shaft |

|

|

|

four* |

Contact part of the paper feed roll and shaft |

G-27 |

AT |

|

five* |

Felt |

0-2 |

BUT |

|

6 * |

Carriage guide axis |

0-2 |

BUT |

|

7 * |

Paper Reduction Gear Shaft |

G-14 |

AT |

|

eight* |

Reducing gear of paper feed (1/3 of perimeter) |

G-14 |

AT |

|

|

Note. |

|

|

|

|

* - lubrication is required during the assembly process. |

|

|

A - grease every six months.

B - lubrication at every major overhaul.

Figure 74 - Diagram of disassembly of the matrix printer and the location of lubrication points

Comments

To leave a comment

Diagnostics, maintenance and repair of electronic and radio equipment

Terms: Diagnostics, maintenance and repair of electronic and radio equipment