Lecture

The type of maintenance is determined by the frequency and complex technological operations to maintain the operational properties of the SVT.

GOST 28470-90 "System maintenance and repair of technical equipment for computers and computer science" defines the following types of MOT

Regulated maintenance should be performed in volume and taking into account the operating time provided for in the operational documentation for the equipment, regardless of the technical condition.

Periodic maintenance should be carried out at intervals of time and in the amount established in the operational documentation for the equipment.

Maintenance with periodic control should be carried out with the periodicity of control of the technical state of the telecommunication equipment installed in the technological documentation and the necessary complex of technological operations depending on the technical state of the technical equipment.

Maintenance with continuous monitoring should be carried out in accordance with the operational documentation on the SVT or technological documentation on the results of continuous monitoring of the technical condition of the SVT.

Monitoring of the technical state of the CBT can be performed in static or dynamic modes.

In the static mode, the control values of the voltages and frequencies of the clock pulses remain constant throughout the entire cycle of preventive control, while in the dynamic mode, they are periodically changed. Thus, by creating weighted modes of operation of the SVT, it is possible to identify elements that are critical in reliability.

Preventive control is performed by hardware and in the program ways. Instrumental control is carried out with the help of special equipment, instrumentation and stands and software and hardware systems.

The most effective should be considered software and hardware control in the presence of a developed system of hardware control in the SVT.

Work on troubleshooting during preventive control can be divided into the following steps:

-analysis of the nature of faults on the current state of the SVT;

- control of environmental parameters and measures to eliminate their deviations;

-localization of errors and determining the location of the malfunction with the help of hardware and software tools of the CBT and with the help of additional equipment;

-trouble-shooting; -resolution of the solution of the problem.

For the implementation of THAT, a TO system (STO) is created.

Currently, the most common are the following types of maintenance systems (HUNDRED):

Scheduled maintenance is based on calendar principle and implements regulated and periodic maintenance. These works are carried out with the aim of maintaining the SVT devices in good condition, detecting equipment failures, preventing failures and failures in the SVT operation.

The frequency of scheduled maintenance depends on the type of LTS and operating conditions (number of shifts and load).

Advantages of the system - ensures the highest readiness of the CBT. Disadvantages of the system - requires large material and physical costs. In general, the system includes the following types of maintenance.

(prophylactic):

KO, ETO SVT includes inspection of devices quick test run readiness (operation of devices), as well as the work provided for by daily maintenance (in accordance with the instruction manual) of all external devices (cleaning, lubrication, adjustment, etc.).

During a two-week MOT , diagnostic tests are run, as well as all types of two-week maintenance work,

provided for external devices.

With Monthly MOT provides for a more complete check.

the operation of the SVT with the help of the entire system of tests included in its software. The test is performed at the rated values of the power sources for the preventive voltage change by + 5%.

Preventive voltage change allows to identify the weakest system circuits. Typically, circuits must maintain their performance when the voltage varies within the specified limits. However, aging and other factors cause gradual changes in the performance of the regimens that can be detected in prophylactic regimens.

Testing of the SVT with prophylactic voltage change reveals the predicted malfunctions, thereby reducing the number of hardly cracked malfunctions leading to failures.

During the monthly prophylaxis, all the necessary work is performed, as provided for in the instruction manual for external devices.

With semi-annual (annual) maintenance (service) , the same work is carried out as with monthly maintenance. As well as all types of semi-annual (annual) preventive works: disassembly, cleaning and lubrication of all mechanical components of external devices with their simultaneous adjustment or replacement of parts. In addition, the cables and power lines are inspected.

A detailed description of the preventive maintenance is given in the operating instructions of the individual devices attached to the CBT by the manufacturer.

When servicing by technical condition , maintenance work is of an unscheduled nature and is performed as necessary based on the state of the object (test results), which corresponds to maintenance with continuous monitoring or maintenance with periodic monitoring.

Unscheduled prophylaxis, appointed mainly after the elimination of serious malfunctioning of the CTS, is referred to unscheduled preventive maintenance. The volume of preventive measures is determined by the nature of the malfunction and its possible consequences.

Conclusion of CBT to unscheduled prophylaxis can also be carried out when the number of failures occurring during a certain fixed period of time exceeds permissible values.

The system requires the availability and proper application of various testing tools (software).

The system allows minimizing the cost of operating the CTS, but the readiness of the CTS to use is lower than when using the preventive maintenance station.

With the combined maintenance system, the “younger types of technical maintenance” are carried out as necessary, as with technical maintenance based on the condition based on the operating time and working conditions of a specific type of computerized thermal engineering system or the results of its testing. The implementation of "older types of MOT" and repairs are planned.

The rational organization of the technical service station should provide for the accumulation of static material on the results of the operation of the wireless telecommunications equipment in order to summarize it, analyze it and make recommendations for improving the service structure, improving the efficiency of using the wireless technology, and reducing operating costs.

Maintenance (service), regardless of the adopted maintenance system, can be organized using known maintenance methods.

The method of maintenance (repair) SVT is determined a set of organizational measures and a set of technological operations for maintenance (repair).

Methods of maintenance (repair) are divided on the basis of organization into:

The proprietary method is to provide a workable the state of the CBT by the manufacturer conducting the maintenance and repair of the own-produced CBT.

Autonomous method is to maintain a healthy the state of the SVT in the operation period, when the user performs the maintenance and repair of the SVT on his own.

A specialized method is to provide working condition of the SVT service enterprise, carrying out work on the maintenance and repair of SVT.

The combined method is to provide a workable the state of the CBT user in conjunction with the service company, or with the manufacturer and reduced to the distribution between them of works on the maintenance and repair of CBT.

By the nature of the performance methods of maintenance (repair) are divided into:

-individual

-group;

-centralized.

In case of individual maintenance , maintenance of one LTS is provided. forces and means of personnel of the SVT. The set of equipment for this type of TO includes:

- control equipment for electronic components and power supply:

- control and adjustment equipment for autonomous testing and repair of SVT tools;

- a set of electrical measuring instruments necessary for the operation of the CBT;

- a set of programs (tests) to test the work of the CBT;

-tool and repair supplies; -support equipment and accessories;

-special furniture for storage of property and equipment of workplaces of the operator and adjuster of the element base.

All of the above equipment provides for the ability to quickly troubleshoot using bench and test equipment. This kit, in combination with the necessary spare parts and accessories (spare tools, devices) should ensure the specified recovery time for the CTA.

With the necessary service equipment and qualified technical personnel, an individual service can significantly reduce the recovery time of the CBT, but at the same time requires significant costs for the maintenance of technical staff and service equipment.

The effectiveness of the operation of the SVT largely depends on the qualifications of the attendants, the timeliness of the maintenance and repair work and the quality of their implementation.

Group THAT serves to serve several CBT, concentrated in one place, by means and forces of specialized personnel. The structure of the equipment in the group service is the same as in the case of an individual, but it also assumes the presence of a larger number of equipment, devices, etc., excluding unnecessary duplication. The group service package includes at least a set of equipment for individual service of the CBT, supplemented by equipment and accessories of other CBT.

Centralized maintenance is more progressive form of service SVT. The centralized maintenance system is a network of regional service centers and their branches - technical service points.

With centralized service, the costs of maintaining technical staff, service equipment and spare parts are reduced. This service involves the repair of elements, components and blocks of SVT on the basis of a special workshop, equipped with all necessary equipment and instruments. In addition, centralized maintenance allows you to concentrate in one place materials on the statistics of failures of elements, assemblies, blocks and devices of SVT, as well as to obtain operational data from dozens of similar SVT with direct control of reliability. All this makes it possible to use the information to predict the required spare parts and equipment, to issue recommendations on the use of SVT.

The type of repair is determined by the conditions of its conduct, the composition and content of the work performed at the LTS.

Repair of SVT is divided into types:

Maintenance repairs should be carried out to restore the performance of the CBT without the use of stationary means of technological equipment at the place of operation of the CBT. In the event of current repairs, the monitoring of the SVT for operation is carried out using appropriate means of verification.

Medium repairs should be carried out to restore the health of the SVT, or components of the SVT using specialized stationary means of technological equipment. With average repairs, the technical condition of the individual components of the CBT is checked with the elimination of detected faults and bringing the parameters to the stipulated norms.

Overhaul should be carried out to restore the performance and resource of the SVT by replacing or repairing the components of the SVT, including the basic ones, using specialized stationary technological equipment in stationary conditions.

Medium and capital repairs of the SVT or their components are, as a rule, planned and are made on products for which the turnaround time is determined and (or) the service life (resource) is limited.

One of the main characteristics of SRT is the duration of SVT prophylaxis . The duration of prophylaxis is more influenced by the qualification level of the staff.

Analysis of static data on the operation of a specific SVT makes it possible to make recommendations on how to replace prophylactics of lesser periodicity with prophylaxis of greater frequency (for example, daily ones - on weekly ones). This allows you to increase the time of use of SVT directly to the computational work.

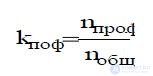

Another important quantitative characteristic is the efficiency ratio of prevention k prof. , which characterizes the degree of increase in the reliability of SVT by preventing failures at the time of prevention. The ratio of the effectiveness of prevention is calculated by the formula

where npr. - the number of failures detected during prophylaxis; n total + npr. - the total number of failures of SVT during the operation period.

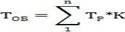

The calculation of the number of employees required to perform service maintenance and current repair of the PC (Ch) is carried out according to the formula:

where: Nr.v - the norm of working time per employee for the planned year

(2000 hours);

Tob - the total time spent on maintenance of computer equipment is calculated by the formula:

Where Tr - time standards for a particular type of work; n - the number of types of work performed;

K = 1,08 - the correction factor that takes into account the time spent on work, not stipulated by the rules and having a one-time nature.

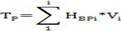

Regulatory time spent on a particular type of work is calculated by the formula:

where Nvri - the rate of time to perform the i-th operation on the unit of measurement in a certain type of normalized work;

Vi is the volume of i-th type of operations performed per year (determined according to accounting and reporting data).

The range of changes from 1 to i is the number of normalized operations in a particular type of work.

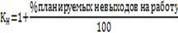

The basis for the compilation of the staffing table for the number of employees is the average number (PC), which is calculated by the formula:

Chsp = Chn x Kn, where Kn - coefficient taking into account the planned absenteeism of workers

during vacation, illness, etc., is determined by the formula:

,

, where% of planned absenteeism is set according to accounting data.

The quality of SVT operation depends on providing it with spare elements, various devices, consumables, providing instrumentation, tools, etc. The creation of the necessary conditions for the normal functioning of computing facilities (temperature and humidity conditions, power supply, etc.) is also of great importance. . p.) and for service personnel (climatic conditions, noise level, illumination, etc.).

The operation of the CBT must be carefully planned. Planning should cover the whole range of issues related both to the compilation of the general program of work of the CTS, distribution of computer time, etc., and to the entire work of the service personnel.

The rational organization of operation should provide for the accumulation of static material based on the results of the operation of the wireless telecommunications equipment in order to generalize it, analyze it and make recommendations for improving the service structure, improving the efficiency of using the wireless technology, reducing operating costs.

Comments

To leave a comment

Diagnostics, maintenance and repair of electronic and radio equipment

Terms: Diagnostics, maintenance and repair of electronic and radio equipment