Lecture

Thermistor based temperature sensor

The thermistor symbol used in the circuits

Volt-ampere characteristic (VAC) for posistor.

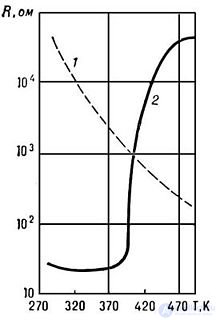

The dependence of the resistance of the thermistor on the temperature.

1 - TKS <0

2 - TKS> 0

A thermistor is a semiconductor resistor that uses the dependence of the electrical resistance of a semiconductor material on temperature [1].

The thermistor is characterized by a large temperature coefficient of resistance (TCR) (tens of times higher than that of metals), simplicity of the device, ability to work in different climatic conditions with significant mechanical loads, relatively low long-term stability of characteristics.

Invented in the distant 1930 by the scientist Samuel Ruben, to this day this component finds the widest application in technology.

Thermistors are made of various materials, the temperature coefficient of resistance (TKS) of which is quite high - significantly exceeds metallic alloys and pure metals, that is, from special, specific semiconductors.

The thermistor is made in the form of rods, tubes, discs, washers, beads and thin plates, mainly using the methods of powder metallurgy. Their sizes can vary from 1–10 microns to 1–2 cm.

The main parameters of the thermistor are: nominal resistance, temperature coefficient of resistance, operating temperature range, the maximum allowable power dissipation.

The thermistor was invented by Samuel Ruben in 1930. [2]

There are thermistors with negative ( thermistors ) and positive ( posistor ) TKS. They are also called NTC thermistors (Negative temperature coefficient) and PTC thermistors (Positive temperature coefficient), respectively. With posistors, with increasing temperature, the resistance also increases, and with thermistors, vice versa: with increasing temperature, resistance decreases.

Negative TKS thermistors are made from a mixture of polycrystalline transition metal oxides (for example, MnO, CoO ?, NiO, CuO) doped with Ge and Si, AIII BV type semiconductors, glassy semiconductors and other materials.

There are low-temperature thermistors (designed for operation at temperatures below 170 K), medium-temperature (170–510 K) and high-temperature (above 570 K). In addition, there are thermistors designed to operate at 4.2 K and below and at 900–1300 K. Medium-temperature thermistors with TKS from −2.4 to −8.4% / K and nominal resistance 1–106 Ω are most widely used .

The operation mode of the thermistors depends on which part of the static current-voltage characteristic (VAC) the operating point is selected. In turn, the current – voltage characteristic depends on the design, size, and basic parameters of the thermistor, as well as on temperature, thermal conductivity of the environment, and thermal coupling between the thermistor and the medium. Thermistors with a working point at the initial (linear) section of the current-voltage characteristic are used to measure and control temperature and compensate for temperature changes in the parameters of electrical circuits and electronic devices. Thermistors with a working point on the downstream section of the current-voltage characteristic (with negative resistance) are used as starting relays, time relays, microwave power meters, temperature and voltage stabilizers. The mode of operation of the thermistor, in which the operating point is also on the drop-down section of the current-voltage characteristic (using the dependence of the resistance of the thermistor on the temperature and thermal conductivity of the environment), is characteristic of thermistors used in the systems of thermal control and fire alarm, level control of liquid and bulk media; The effect of such thermistors is based on the appearance of a relay effect in a circuit with a thermistor when the ambient temperature changes or the conditions of heat exchange between the thermistor and the medium.

Thermistors of a special design are also produced - with indirect heating. In such thermistors there is a heating winding isolated from a semiconductor resistive element (if the power released in the resistive element is small, then the thermal mode of the thermistor is determined by the temperature of the heater, that is, the current in it). Thus, it becomes possible to change the state of the thermistor without changing the current through it. Such a thermistor is used as a variable resistor controlled electrically at a distance.

Of the thermistors with a positive temperature coefficient, thermistors made of solid solutions based on BaTiO3 are of the greatest interest. Such thermistors are commonly referred to as posistors. Thermistors with a small positive temperature coefficient (0.5–0.7% / K), made on the basis of silicon with electronic conductivity, are known; their resistance varies with temperature approximately linearly. Such thermistors are used, for example, for temperature stabilization of electronic devices on transistors.

Directly the main resistive element is obtained by powder metallurgy, treating chalcogenides, halides and oxides of certain metals, giving them various forms, such as the shape of disks or rods of various sizes, large washers, medium tubes, thin plates, small beads, ranging in size from units of microns to tens of millimeters .

According to the nature of the correlation of the element resistance and its temperature, thermistors are divided into two large groups - into posistor and thermistor . Posistors have a positive TKS (for this reason, posistors are also called PTC-thermistors), and thermistors have a negative (therefore they are called NTC-thermistors). Thus, with an increase in the temperature of the posistor housing, its resistance also increases, and with an increase in the temperature of the thermistor, its resistance decreases accordingly.

Materials for thermistors today are: mixtures of polycrystalline oxides of transition metals, such as cobalt, manganese, copper and nickel, III – V type compounds, as well as doped, glassy semiconductors, such as silicon and germanium, and some other substances. Remarkable posistors of solid solutions based on barium titanate.

Thermistors in general can be classified into:

Low-temperature class (operating temperature below 170 K);

Medium temperature class (operating temperature from 170 K to 510 K);

High-temperature class (operating temperature from 570 K and above);

Separate high-temperature class (operating temperature from 900 K to 1300 K).

All these elements, both thermistors and posistors, can operate under various climatic environmental conditions and with substantial physical external and current loads. However, in rigid thermocyclic modes, their initial thermoelectric characteristics change over time, such as nominal resistance at room temperature and temperature coefficient of resistance.

There are also combined components, for example, thermistors with indirect heating . In the housings of such devices are placed themselves and the thermistor and galvanically isolated heating element, which sets the initial temperature of the thermistor, and, accordingly, its initial electrical resistance.

These devices are used as variable resistors, voltage controlled, applied to the heating element of the thermistor.

Depending on how the operating point on the IVC of a particular component is chosen, the mode of operation of the thermistor in the circuit is also determined. And the VAC itself is associated with design features and with a temperature applied to the component of the component.

To control temperature variations and to compensate for dynamically changing parameters, such as flowing current and applied voltage in electrical circuits, which change following changes in temperature conditions, thermistors are used with setting the operating point on the linear section of the IVC.

But the working point is set traditionally on the falling part of the IVC (NTC-thermistors), if the thermistor is used, for example, as a starting device, time relay, in the system for tracking and measuring the intensity of microwave radiation, in fire alarm systems, thermal control , in installations controlling the flow of solids and liquids.

Medium-temperature thermistors and posistors with TKS from -2.4 to -8.4% per 1 K are most popular today. They operate in a wide range of resistances from ohms to ohms.

There are posistors with a relatively small TKS from 0.5% to 0.7% per 1 K, made on the basis of silicon. Their resistance varies almost linearly. Such posistor are widely used in systems of temperature stabilization and in systems of active cooling of power semiconductor switches in various modern electronic devices, especially in powerful ones. These components fit easily into the circuit and do not take up much space on the boards.

A typical posistor has the shape of a ceramic disk, sometimes several elements are installed in a single case in series, but more often in a single version with a protective enamel coating. Poisistors are often used as fuses to protect electrical circuits from overloads of voltage and current, as well as thermal sensors and auto-stabilizing elements, because of their unpretentiousness and physical stability.

Thermistors are widely used in numerous areas of electronics, especially where precise control of the temperature process is important. This is relevant for data transmission equipment, computer equipment, high-performance CPUs and high-precision industrial equipment.

One of the simplest and very popular examples of the application of a thermistor is an effective limitation of the starting current. At the moment of applying voltage to the power supply unit from the network, an extremely sharp charge of a capacitor of considerable capacity occurs, and a large charging current flows in the primary circuit and can burn the diode bridge.

This current is limited by a thermistor, that is, this component of the circuit changes its resistance depending on the current passing through it, because according to Ohm's law it is heated. The thermistor then restores its original resistance, after a few minutes, as soon as it cools to room temperature.

Comments

To leave a comment

Electronics, Microelectronics, Element Base

Terms: Electronics, Microelectronics, Element Base