Lecture

The objectives and objects of study of labor processes and working time costs. For scientific and organizational labor and the establishment of technically sound standards in production, it is necessary to study the content of the work and the time spent on its execution by workers and equipment. This study allows you to:

The objects of the study of the cost of working time can be all kinds of costs and loss of working time, highlighting elements of operations and operational time; preparatory-final time * ; work time for servicing jobs; certain types of loss of working time; time to perform individual elements of operations.

Methods for studying the work process are divided into two groups: single-factor , in which one indicator is studied and fixed (for example, time), and multifactorial (complex), in which not one, but a number of production indicators directly related to the process studied are recorded and fixed. For example, when studying the work process of a brigade, the quality of products, the employment of each member of the brigade, and the degree of use of equipment are recorded. Such a comprehensive study of the cost of working time is one of the main means of identifying and using reserves of growth of labor productivity due to further compaction of the working day, better use of technology, improvement of technology, organization of labor and production.

Depending on the goals and technique of observation, the following main methods are distinguished: photograph of working time * , method of moment observations, timing * .

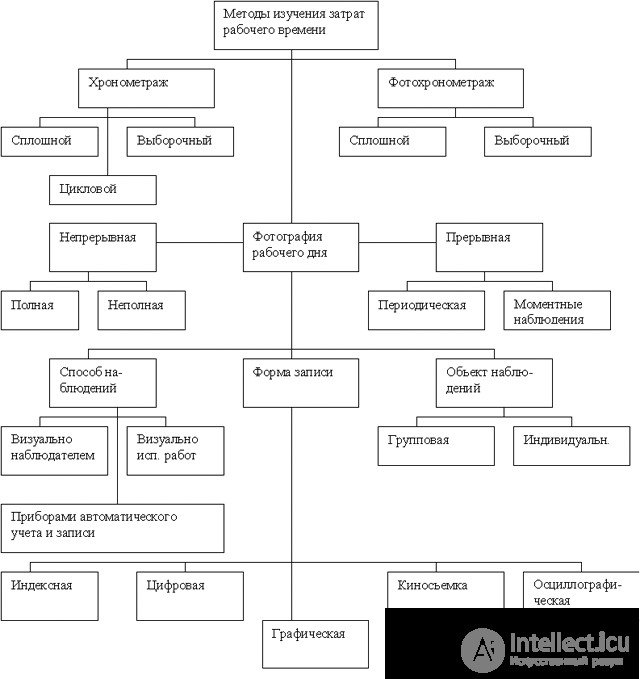

Classification of methods of studying the cost of working time observation is presented in Fig. 8.2.

The classification of the cost of working time. The purpose of the classification of the cost of working time is such a grouping that allows you to objectively analyze the feasibility of the use of working time in relation to performance, equipment and production process.

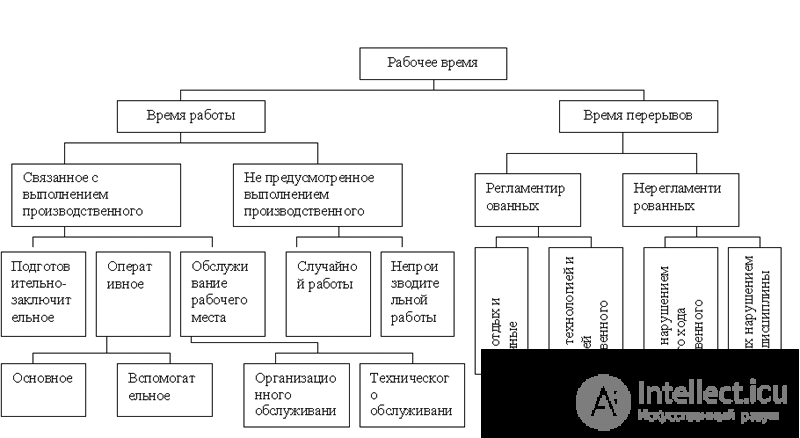

In relation to the contractor, all the costs of working time can be grouped so as to reveal not only the workload, but also the nature of the contractor’s employment during the work day. According to this classification, working time is divided into work time and break time.

Work time is made up of time spent on the production task, as well as on work that is not caused by the task (excessive time). Work time associated with the production task is divided into preparatory and final * operational (main * plus auxiliary * ) and maintenance time of the workplace * (technical * and organizational * ). Breaks in work can be of two types: regulated (necessary) and unregulated (redundant).

By the preparatory-final time is the time required to get acquainted with the work ahead, prepare for it and complete it. This time is spent once for the whole batch of parts to be machined or once for the whole working day. The share of the cost of this time depends on the type of production and the nature of the work performed. It reaches its maximum value in the conditions of a single production, where frequent turnover of work (detail of operations) at workplaces. In mass production, preparatory-final time is small.

The main (technological) time is the time during which the process is directly carried out.

Auxiliary time is spent on activities related to the preparation for the main (technological) work. For example: the time of installation and removal of the product, the approach and removal of the tool, the start and stop of the mechanism, selective measurements of the product, verification of technological regimes, etc.

Workplace maintenance time is the time that a worker must spend on caring for a workplace (mechanism, tool, fixture) during a given particular job and work shift.

Fig. 8.2. Classification of methods of studying the cost of working time observation.

The time of maintenance of the workplace * is spent on changing the tool, adjusting and adjusting the mechanism in the process of working, editing the tool and similar actions of the worker related to the care of the workplace during a certain specified work.

The time of organizational maintenance * of the workplace covers the time spent by the worker on caring for the workplace during the work shift (layout and cleaning of the tool at the beginning and end of the shift, lubrication and cleaning of the mechanism, cleaning of the workplace).

The time of regulated breaks consists of time for rest and personal needs, as well as breaks caused by the organizational and technological features of the process.

Unregulated interruptions in work occur mainly due to organizational or technical problems, due to violation of labor discipline.

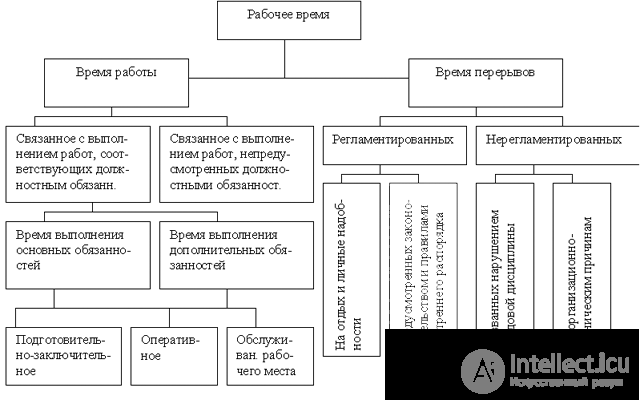

Classification of the cost of working time of workers is presented in Fig. 8.3., Managers and specialists in fig. 8.4.

Fig. 8.3. Classification of working time workers.

Photo working time. Under the photograph of working time (FRV) refers to the method of research of the labor process in order to identify the cost of working time during the study period (usually the whole shift).

With the help of the FRV, the following tasks are solved:

Fig. 8.4. Classification of the cost of working time of managers and specialists.

Observations are carried out on one worker or on a group of workers, respectively, distinguish individual and group photographs of working time. FRV consists of four stages.

Preparation for observation is to establish the purpose of observation, to choose the objects and method of observation, to get acquainted with the object of observation and the system of organizing the maintenance of workplaces, to prepare everything necessary for conducting observation (observation sheets, time devices, etc.).

When conducting individual FRV, observations and recordings are kept at the current time, when all the actions of the worker are recorded with the start time of each next action. In case of deviations, the observer fixes comments to the defective records, the worker’s actions are also recorded in the observation sheet, allowing to reveal (or hide) the shortcomings in the organization of labor.

The processing of observation materials is reduced to the determination of the duration of each record, the indexing of the category of the cost of time and the compilation of a report of the same cost of working time.

The findings and development of organizational and technical measures to eliminate unnecessary time costs are based on a summary of time expenses of the same name, in which the total time is entered for each category and the relation to the total time is determined.

Determined the percentage of operating time:

K ov = (t op / T n ) · 100,

where T n is the observation time, min .;

percentage of loss of working time, depending on the workers;

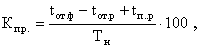

where t from. f is the time of actual rest; t from .r - regulated time for rest and personal needs; t p.r - loss of working time allowed by the workers;

percentage of loss of working time, independent of the worker

where t n. p. and t p.o - loss of time for production work and for organizational and technical reasons, respectively.

Loss of working time is a reserve for increasing productivity. To determine the possible increase in labor productivity are normal and the actual balance of working time. The normal balance is according to the standards without seeing the work performed (table 4), and the actual on the materials of the photo.

Percentages of a possible increase in labor productivity are established by eliminating the loss of working time, depending on the worker,

a 1 = (100 · K p. p ) / (100 - K p. p ),

as well as loss of working time for organizational and technical reasons and for unproductive work

a 2 = (100 · K p. ) / (100 - K p. ),

Overall potential increase in labor productivity

a = a 1 + a 2 .

When a large number of objects of observation is a group photograph of working time. When it uses the methods of periodic recording at certain, predetermined intervals.

The content of the preparation for the observation is similar to the individual FRV, but is supplemented by the particular characteristics of the groups of workers, equipment and industrial buildings. In strictly observed periods and with the order of visiting objects, the observer for each of them fixes with the indexes the content of the work or breaks in the work. At the end of the observation, a summary of the same expenses for each observed object is compiled, the conclusions and the development of measures are carried out similarly to individual PRFs.

The method of moment observations. With the need for simultaneous observation of a large number of objects using the method of instantaneous observations, based on the application of probability theories in mathematical statistics. When studying the cost of working time using this method, the number of observations (moments) should be large enough to correctly characterize the phenomena being studied and to ensure the desired accuracy of the results, the duration of a series of observations should be sufficient to coverage of work items.

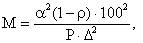

The general formula for determining the number moments (observations) has the following form:

Where  - the coefficient that determines the level of probability of failure of the observation error for the established limits; R is the probability of employment of a worker or machine by performing a job, characterized by their load factor (the specific weight of the time spent associated with the work being studied, or equipment operation time), I-P is the probability that the worker or machine is in a state of inactivity (the proportion of interruptions in the work of the machine or idle machine);

- the coefficient that determines the level of probability of failure of the observation error for the established limits; R is the probability of employment of a worker or machine by performing a job, characterized by their load factor (the specific weight of the time spent associated with the work being studied, or equipment operation time), I-P is the probability that the worker or machine is in a state of inactivity (the proportion of interruptions in the work of the machine or idle machine);  - permissible relative error of the observation results (usually

- permissible relative error of the observation results (usually  from value: P).

from value: P).

In mass production, large-scale production is usually satisfied with a confidence level of 0.64, which corresponds to  2 = 2. In medium-and small-scale production, in order to obtain greater confidence in the reliability of the results of observations, a confidence level of 0.92 is assumed ( L 2 =

2 = 2. In medium-and small-scale production, in order to obtain greater confidence in the reliability of the results of observations, a confidence level of 0.92 is assumed ( L 2 =  .) . Depending on the type of production, special tables have been developed to determine the number of moments of observation.

.) . Depending on the type of production, special tables have been developed to determine the number of moments of observation.

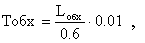

The duration of one round T T the x is determined by the formula

Where L about - the length of the route to bypass jobs, m; 0.6 is the average length of one step, m; 0.01 - the average duration of one step, min.

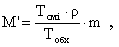

The number fixed in one shift of the moments M ' will be

Where  coefficient taking into account the discrepancy between rounds (deviations), 0.5 <

coefficient taking into account the discrepancy between rounds (deviations), 0.5 <  <0.7; m is the number of objects of observation with one bypass.

<0.7; m is the number of objects of observation with one bypass.

The number of work shifts required for observation is determined by the formula

C n = M / M '

When the observer sequentially traverses the objects, the state of each of them is currently recorded in the map of moment observations, the final result of monitoring the shift by time cost categories is determined by counting the number of corresponding marks (fixed moments) for each of the indices and the machine (workplace) and total for the site with the definition of the cost structure. Further, as with the FRV, they analyze the time spent, develop office equipment to eliminate the loss of working time and determine the indicator of a possible increase in labor productivity.

Timing * . Under the timing refers to a method of studying the contents of the operation, the sequence of its implementation and measuring the cost of working time to perform individual cyclically repetitive basic and auxiliary elements of the operation.

The purpose of timing: obtaining baseline data for the development of standards of time for the elements of work; setting time limits for individual operations; check and clarify the time standards established by the method of technical calculation; the study, synthesis and dissemination of rational methods and techniques for the work of advanced workers; verification of the possibility of combining in time labor actions and movements that were not taken into account when calculating the norms for standards; synchronization of work on production lines and conveyors in order to fully load the units and workers - operators.

The timekeeping process consists of several stages.

Preparation for timekeeping observation is to justify the choice of workplace on the structure of the operation, and its compliance with equipment, working conditions and worker qualifications; dividing the operation into its constituent elements - complex receptions, receptions or movements; identifying factors affecting the duration of each element. This stage ends with the inclusion of the listed information and operation elements with fixing points on the observation sheet.

Under the fixation point understand the point in time. in which the end of the last movement of the previous reception coincides with the beginning of the first movement of the subsequent reception of the operation.

Timing observation comes down to measuring and fixing the duration of each normalized element of an operation with the help of time devices (stopwatches, chronometers, special time recorders). According to the method of conducting distinguish continuous and selective timing. With continuous timekeeping, the current time to perform all the techniques of the technological operation is continuously measured. With selective timekeeping, only the duration of individual standardized receptions is measured, regardless of their sequence. For timekeeping * and subsequent data processing use a special time-observation sheet.

Processing and analysis of the results of observation at the time spent on the current time are as follows: for each element of the operation, the duration of this element of the previous element is determined by the current time of this element of the previous element; from the formed time series exclude the defective elements noted during the observation; for each chronory, the stability factors K y = t max / t min are determined, where t max and t min are the maximum and minimum duration of the element, respectively. The actual values of the sustainability coefficients of the received chronorials should not exceed the standard values.

Timing series of manual techniques are less resistant than the rows of machine-manual works.

The closer the value of the coefficient of stability K y to. Unit, the higher the stability of the series.

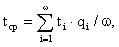

For a stable chronorium, the time standard for the operation element is defined as the arithmetic average value.

where t i - the private value of the i - th duration (options) in this series;

q i -the repeatability of the value of the i-th variant (frequency);  - the number of members (measurements) remaining in the row after its processing.

- the number of members (measurements) remaining in the row after its processing.

Comments

To leave a comment

Management

Terms: Management