Lecture

The concept of jobs and their classification. The most important part of the work package for improving the organization of work at enterprises is to improve the organization of workplace services (RM). RM should be considered as the primary link of the production process, its organizational and technical basis.

The workplace is part of the production area with the location on it of technical, auxiliary, lifting and transport equipment and devices, equipment and various equipment needed by the performer or group of performers to perform the production task.

Organization (RM) is a set of activities that include: rational specialization of the Republic of Moldova; equipping * it with the required sets of main and auxiliary equipment; tooling and inventory; creation of comfortable working conditions; optimal placement of equipment, convenient placement of equipment and objects of labor on the Republic of Moldova; uninterrupted maintenance of the RM in accordance with its functional needs.

The specific composition and content of work on the rational organization of the RM depends on a number of factors: industry, type of production, type of labor, degree of cooperation and. division of labor, levels of technical equipment and mechanization of labor, working conditions, etc.

One or another combination of these factors generates a variety of forms of concrete labor in instrument making and, accordingly, a large variety of RM, the ordering of which is facilitated by the classification of RM.

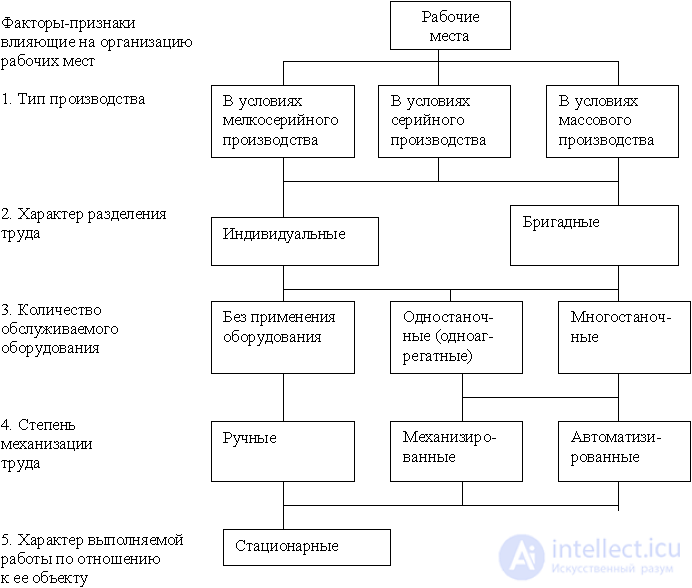

Under the classification of the Republic of Moldova refers to the distribution of their totality according to the main factors - the signs that determine the final homogeneity of the characteristics and properties of the formed groups of jobs. The scheme of PM classification is shown in fig. 8.5.

Proper attribution of the RM to the classification group is of great importance for its rational organization, identifying the characteristics and ways to improve each element of the RM.

Fig.8.5 Classification of jobs

Equipment jobs. * An important role in solving the tasks of the scientific organization of labor is assigned to the issues of equipping the Republic of Moldova.

Under the equipment of the Republic of Moldova is understood the whole set of the main technological and auxiliary equipment located in its zone, technological and organizational equipment, signaling means, safety measures, etc.

The equipment of the RM is determined by their production profile, specialization and degree of mechanization and automation of technological processes. The determining factor in equipping the RM is the type of production, and hence the level of specialization of the RM.

Depending on the type of production and equipment used, RMs are divided into special (used in mass production), specialized (used in large and medium-scale production), universal (used in small-scale and individual production).

The workplace equipment complex includes the following components:

Workplace planning * . The planning of a workplace means a large-scale layout for placing a specific area of the production area (in the workplace area) of all elements of its equipment and creating various optimal zones to ensure the most comfortable and safe working conditions for primary and secondary workers.

There are external and internal layout of the RM. The external layout of the RM determines the rational placement of the main technological and auxiliary equipment, inventory and accessories. It should provide the minimum trajectory of movement of the worker in the process of doing the work, the maximum reduction of unnecessary movements of human working bodies, economical use of the production area.

The internal layout of the RM determines the rational placement of tooling and tools in the appropriate cabinets for this, the correct location of workpieces and parts on the PM. The internal layout should provide a comfortable working posture, uniform implementation of labor movements with both hands. The sizes of the reach zones depend on the working posture (standing or sitting) and the anthropometric data of the working research institute, and typical schemes of the zones of normal reach are developed and recommended.

The rationality of the layout of the RM is estimated using the occupancy rate of the production area

where n is the number of units of the main, auxiliary equipment of inventory at the RM; f i is the production area occupied by the i-th unit of equipment (standard); Frm - the production area of the workplace according to its layout. Elements of equipment should be placed in accordance with the existing standards of coordination of the RM zone with the highest occupancy rate of the production area (on average, K F = 0.4? 0.65).

Service jobs. The productivity of labor, the rhythm of production, and the quality of products depend on the efficiency of the organization of the service system of a RM. The study of the causes of the loss of a working shift showed that about 70% of the intra-shift losses are due to poor organization of the maintenance of the Republic of Moldova, from which follows the urgency of improving it.

The RM service includes the following functions: production and preparatory (provision of the RM with technical documentation, blanks, materials); transport and loading and unloading (delivery of objects of labor to PM, export of finished products and disposal of industrial waste); equipment (provision of tools and accessories); adjustment (adjustment of machines and other technological equipment); energy (provision of PM energy); control (quality control of raw materials, finished products); turnaround (equipment repair); warehouse (warehousing, accounting, storage and distribution of materials and finished products); household (maintaining cleanliness and order in the Republic of Moldova).

The basic principles of PM service: planning, courtesy, complexity, timeliness and cost-effectiveness.

Planned maintenance is achieved through consistency with the operational planning of the main production process and provides a clear sequence of support services and workers in accordance with the content of the main process.

The precaution of maintenance is preventive in nature and is expressed in the preliminary acquisition of working documentation, tools and devices, in the complex implementation of equipment adjustments and its preventive repair.

Complexity of service is achieved by the consistency in time of all types of service.

Timeliness - in elimination of problems arising in the course of work in a short time.

Efficiency - in the minimum cost of material and labor resources for the maintenance of the Republic of Moldova.

Depending on the type of production, the complexity of manufactured products and other specific conditions, the following forms of service are distinguished: on duty and preventive.

The duty officer , as a rule, is carried out by auxiliary workers of the shop services. It is characteristic of small-scale and single-unit production and is based on shift-daily tasks, signals from the Republic of Moldova, by order of the master or dispatcher.

Planned preventive measures are used in serial production and consist in organizing work on the maintenance functions (repair, production and preparatory) by specialized auxiliary services of the enterprise and workshops on the basis of calendar schedules. Its most perfect form is the standard service of the Republic of Moldova. This form is typical for mass production.

The project of organization and maintenance of the Republic of Moldova is drawn up in the form of a specialized card of the organization of labor and the workplace, which has gained the status of a passport or enterprise standard. On the front side of the card are the details: operation, discharge and qualification of the worker, the layout of the RM, the trajectory moved by the worker and parts; equipment; technological, organizational and technical equipment of the Republic of Moldova.

On the back side, the rational structure of the labor process, the factors influencing the performance of the labor process are indicated. and its duration, types, forms and terms of service of the Republic of Moldova, an indicator of optimal working conditions.

The organization of workplaces of managers and specialists. When organizing RM managers, such features of their work as extensive information communications, constant contacts with a large number of people, the need to make operational decisions, and control over the implementation of decisions are crucial.

Taking into account these features, plan and equip the leader of the Republic of Moldova. Great attention should be paid to furniture, office equipment, communication of small computers and equipment. The organization of RM specialists depends on the specifics of their work. Along with special equipment related to the specifics of a particular work, the RM specialists should be equipped with “small” office equipment, including mechanical reference books, a set of stationery.

Employees' workplaces are usually located in common halls or isolated premises (depending on the type of work, the number of performers and their interconnection). In the common halls of the Republic of Moldova are usually arranged in parallel rows. but if workers are not interconnected by one occupation, then RM can be separated by partitions. The equipment of PM * employees is made depending on the specifics of their work. At present, typical planning of the RM * of various categories of workers, developed in the relevant directories and which it is expedient to use when organizing the PM of a particular employee, has been developed.

Comments

To leave a comment

Management

Terms: Management