Lecture

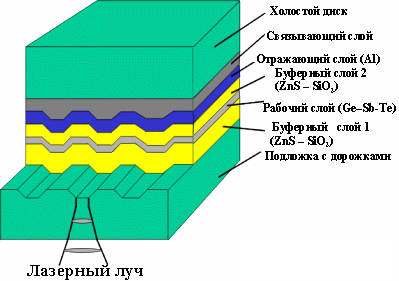

The basis for recording and storing data on DVD-RAM and DVD-RW discs is the technology of changing the phase state of a substance. When recording and reading information, the difference in surface reflectivity is used depending on whether it is in a crystalline or amorphous state.

When reading information from a disk, the difference between dark amorphous and bright transparent zones is measured. This technology can be called optical - only a laser is sufficient for reading and writing. The layer structure of one half of the disk is shown in the figure.

DVD formats

The current DVD standard allows for several different disc designs. These are single-sided or double-sided discs, with one or two information-carrying layers on each side.

A single layer 0.6 mm thick can fit up to 4.7 GB of information, and the entire disk up to 17 GB.

Four types of DVDs are possible: DVD-5, DVD-9, DVD-10 and DVD-18.

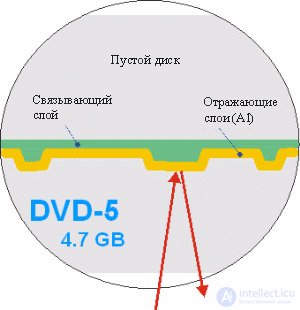

DVD-5

DVD-5 is the first market version of a DVD: single-sided disc with single-layer recording and a capacity of 4.7 GB.

The DVD consists of 0.6 mm film coated with aluminum and glued onto a clean substrate. Spray technology is the same as used in the manufacture of conventional CD. Aluminum film has a thickness of 55 nanometers, as well as for audio CDs and CD-ROMs. The structure of the DVD-5 is shown in the figure.

DVD-9

DVD-9 is a two-level single-sided disc with a capacity of 8.5 GB. For the production of such a disk, you must create a translucent layer that reflects 18-30 % of the laser radiation. This is enough to allow information to be read from the top layer. And at the same time, the translucent layer will transmit enough radiation so that the signal from the lower level with high reflectivity is also readable. Informational levels are shared by highly homogeneous glue (the thickness of the adhesive layer is 40-70 microns), used to join the two halves of the disk. This distance is necessary to distinguish the signal reflected from one and the other levels. The structure of the DVD-9 is shown in the figure.

The use of a translucent layer dictates more stringent requirements for the material and technology used:

On the one hand, the optimal material for the translucent layer is gold. On the other hand, the use of gold instead of another material will help reduce production costs by 70%.

Today, silicon and silver alloys are used as an alternative to gold.

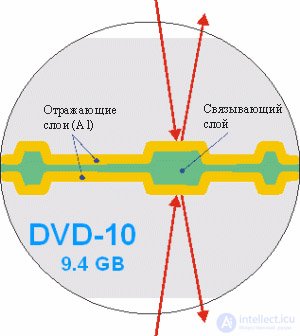

DVD-10

DVD-10 is a single-layer double-sided disc with a capacity of 9.4 GB.

In principle, this is a double DVD-5 without a clean substrate. Two discs covered with metal films are joined together. To read information from two sides of a disk, one laser is used.

The following figure shows the structure of a DVD-10.

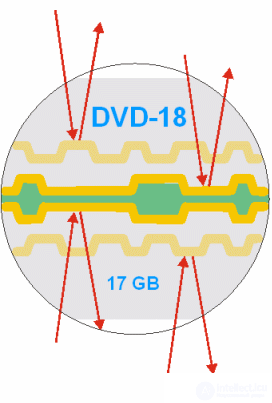

DVD-18

The structure of a DVD-18 is basically the same as that of a DVD-9, but a DVD-18 can be read from both sides.

The result is double capacity compared to DVD-9.

The basic structure of the disk in the figure.

Optical recording

In recent years, optical recording using a change in the phase state of a substance has progressed significantly. Now it is a complete technology for creating rewritable media.

In addition to the general advantages of contactless reading of information, optical recording technology is compatible with the widespread CD standard.

Principle of operation

The laser beam causes crystallographic changes in the active layer of the optical disk (namely, as a result of irradiation, the substance changes its state from crystalline to amorphous and vice versa).

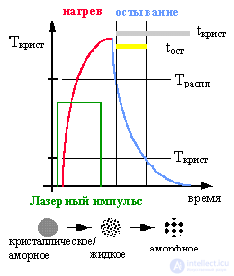

Recording information |

A record of amorphous regions is shown in this graph. A short high-power laser pulse melts the recording material (the heating temperature exceeds the melting point of the material, T> T melt). This is followed by cooling below the crystallization temperature (T crista).

The result of cooling is to prevent the formation of crystallization centers. thus, the growth of the crystalline phase does not occur, and the substance remains in the amorphous state.

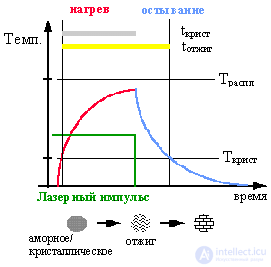

Data erasure |

The following graph explains the data erasure mechanism. To erase it is necessary to return the substance to the crystalline state. Again, with the help of a laser, an amorphous substance is heated to a temperature T, which is less than the melting point, but greater than the crystallization temperature (T crista <T <T melt). Heating (or rather, annealing) lasts for a time (t ej), sufficient to restore the crystalline state of matter. This time must be longer than the so-called crystallization time (t crista, t crista <t hw).

If you need a very fast recording, for example for DVD-RW, then rapid crystallization is vital. Therefore, the time t of the crista should be below 100 nanoseks, and this strictly limits the choice of material used. Optimal use of various alloys of Ge, Sb and Te - they not only satisfy the requirements for the time of crystallization, but also have a large optical contrast between the amorphous and crystalline phases. In addition, they have acceptable crystallization and melting temperatures (TC = 150–200 ° C, TP = 600 ° C).

Recording mechanism

An essential part of each method, based on a change in pulse duration, is the use of a multipulse write strategy.

Each recorded label is formed by high-power laser pulses (P write = 12 mW, pulse duration 15 ns). Between pulses, the intensity of the laser radiation decreases. Thus, after each pulse, the molten material is cooled to a temperature below the crystallization temperature, forming a region with an amorphous phase. Erasure (i.e. crystallization) is achieved by a long laser pulse (P erasing <P records). Reading information is already at a much lower laser power (P reading = 0.5-0.6 mW).

Method of direct rewriting of information |

The label is recorded by a series of powerful pulses. Erasure is achieved by long-term laser exposure with a power Pw <P recording.

Comments

To leave a comment

Electromechanical devices of electronic devices

Terms: Electromechanical devices of electronic devices