Lecture

Lecture questions:

1. Qualification assessment method

2. Calculation of single and generalized indicators of properties

3. Quality log

4. The calculation of the final indicator

Differential method for assessing product quality

carried out by comparing the indicators of individual

properties of the evaluated sample with the corresponding indicators

mi base sample. At the same time, it is determined by how many

quality of the evaluated product to the quality of the base sample

in general, and what indicators of the properties of the product being evaluated are pre-

ascend or do not correspond to the base sample,

and how similar are similar to each other

properties

In the differential method of quality assessment,

are the most significant properties of the object and are conventionally considered

as equivalent. The number of such properties taken into account

that facilitates the process of assessing the quality level

delivered objects.

Differential quality assessment method is first

queue qualification method that allows you to evaluate

for example, technical products for such quality categories,

as “superior”, “compliant” or “non-compliant”

a certain (for example, world-wide) quality level of a similar

products. At the same time, with the differential method

ki product quality quantified individual

product properties that allow you to make specific decisions

on the quality management of this product.

2. Calculation of single and generalized

property indicators

In the differential method of assessing product quality

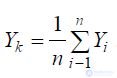

calculate levels of single and / or generalized indicators

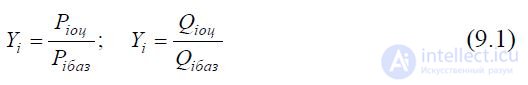

properties according to the formulas:

or

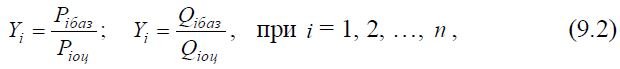

, with i = 1, 2, ..., n ,

where Piоts and Qiоts are the values of the i -th single and generalized indicator of the properties of the product being evaluated;

Pibaz and Qi bases - the values of the i- th indicator of the base sample;

n is the number of relevant indicators adopted for quality assessment.

Formula (9.1) is used when the increase in the absolute

lute value of the quality indicator corresponds to the improvement

quality products. So, for example, the relative performance indicators are

performance, power, efficiency,

service life is calculated by the formula according to this formula, since

an increase in their values indicates an improvement in product quality.

In other cases, when increasing the absolute value

property indicator characterizes deterioration in the quality of products

tion, then to calculate the relative value of the indicator

use the formula (9.2). According to this formula is usually calculated from

the relative values of indicators such as material consumption;

consumption of materials, fuel, energy; the content of harmful substances

this waste, labor intensity; bounce flow parameters, etc.

Formulas (9.1) and (9.2) are valid subject to the absence

restrictions in the values of individual indicators of quality. With

the presence of such restrictions values of relative indicators

calculate with these restrictions to the limit values of Pp

In this case, for example, the first of formulas (9.1) transforms

to the form:

where Ppr i is the limiting value of the i -th parameter.

According to the results of calculations of relative values

the properties of the compared products and their analysis give the following

unconditional estimates:

- the level of product quality is higher or equal to the level of

base sample if all values of relative indicators

respectively, greater than or equal to one;

- the quality level of the product being evaluated is below the level

The base sample, if all or most of the values are from

personal indicators less than one.

For example, given the indicators of the basic properties of the tractor T and

two basic tractors (tab. 7).

Table 7 Indicators of the properties of tractors and their numerical value

Note. The sign "+" means the deviation of the indicator for the better,

the sign "-" means worse

Qualification assessment of the technical level of the tractor T

produced by the six parameters of three groups: destination (but

mine power and speed), reliability (in

rework on failure and resource before the first overhaul), eco-

resource names

(specific fuel consumption and labor intensity

Maintenance). From the table it can be seen that

tractor T surpasses one analog only in engine power

For, and all other indicators are inferior to both peers. Conclusion:

tractor type T is inferior (does not correspond) to the world level.

The technical level of the evaluated products, for example,

tire construction, for which the importance of each

This indicator is recognized below the TU of the baseline

sample, if at least one of the relative indicators is less than

above units.

In cases where part of the relative indicators

properties is greater than or equal to one, and the other part is less than one

nits, i.e. when there is some uncertainty in the assessment

product quality, it is recommended to use the following

evaluation method. All relative indicators needed

properties divided by significance into two groups. In the first (o

new group should include indicators characterizing

the most significant properties, and in the second - minor.

If it turns out that in the first group all relative indicators

whether it is greater than or equal to one, then we can assume that the quality

estimated product is not worse than the quality of the base sample.

For a more accurate and more informative assessment of the specification,

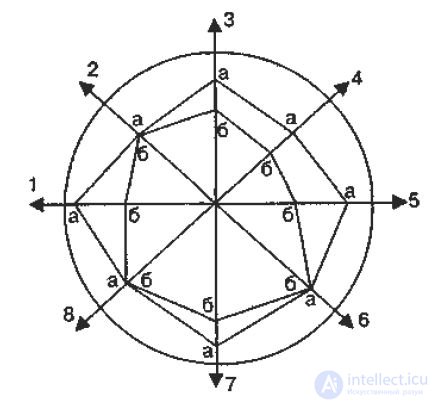

characterizing the quality of the product, build a chart comparing

quality indicators (cyclogram), which clearly

shows which indicator should be used for management

and technical solutions.

In fig. 8 in a simplified form is shown the cyclogram of a certain

dividing the technical level in terms of quality

basic and basic products using eight basic

properties presented on eight qualimetric scales

lah.

Fig. 8. The sequence diagram for determining the quality of products:

1 - performance; 2 - specific gravity; 3 - coefficient

automation; 4 - reliability; 5 - annual yield;

6 - specific occupied area; 7 - aesthetic indicators;

8 - specific installed electric power

The scales lay the values of the indicators estimated

product (point b) and analogue (point a). Points connect between

and get two polygons. Polygon forming

points “a”, characterizes the set of properties of the analogue

hectare or base sample, and the polygon formed by the dots

b, is the set of properties of the product being evaluated.

From the cyclogram ("web of quality") it is clear that the area

occupied by the polygon properties of the product being evaluated,

less than the area occupied by the polygon properties of the analog.

This suggests that TU and, therefore, quality

the set of properties is inferior to the level of analog, non-

despite the fact that the values of individual indicators of the product

(specific weight, occupied area, installed electrical

power) equal to the values of these indicators analog. OK-

The strength on the cyclogram characterizes the ideal quality, i.e.

quality that can be achieved. On the axes (scales)

standing from the center to the circle corresponds to the limit

value of the parameter - property indicator.

Quantitatively, the value of the final quality indicator,

those. quality level (Yk), can be calculated as a definition

arithmetic mean value of all levels considered

properties (Yi), matched (estimated and base) samples (objects), that is, as

For example, in engineering to determine the TU machines and

devices use a number of indicators that are usually divided

on the main and additional.

The main indicators of quality include indicators designated

maintenance or operational, reliability, economical

use of raw materials, materials, fuel, energy, ergonomic

and aesthetic, indicators of manufacturability, transport

simplicity, standardization and unification.

Additional indicators usually include patent

legal and some others.

If the distribution of relative indicators of properties

other and more complex, the technical level assessment is necessary

implement using integrated or mixed methods.

Comments

To leave a comment

Qualimetry reliability and quality

Terms: Qualimetry reliability and quality